"Previous Attemps"

The content of this page will briefly mention the past 3 iterations of the Filament Extruder Machine.

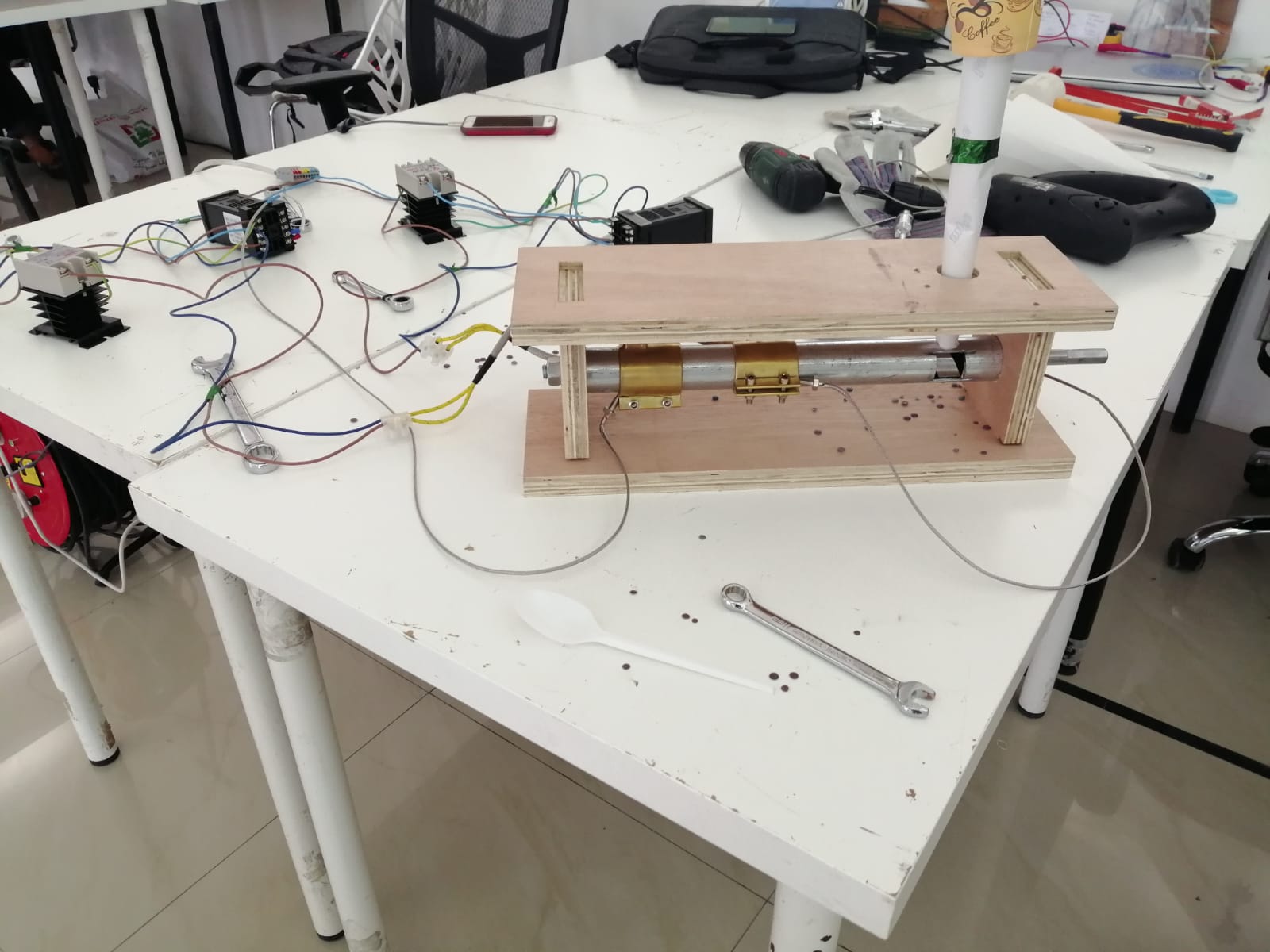

First iteration was made from a galvanized steel pipe, fitted on a wooden frame, with two heater bands attached to the pipe. The pipe is cut from the top to facilitate material insertion, and a manually operated auger drill drives the material into the nozzle side. The nozzle is basically made from a drilled screw. First iteration was performed with mixed plastic pellets.

Insight gained from first iteration: Mixed plastic pellets melt at higher temperatures than PLA, which wasn’t accounted for. As a result, it quickly solidified and blocked the movement of the auger drill. This made operating the machine difficult.

Second iteration was basically the same setup, but with PLA.

Insight gained from second iteration: Size of the pipe required a large amount of PLA to be able to drive the machine, and as a result, PLA simply refused to move throughout the pipe and stayed in place, due to the lack of a moving force.

The lack of a nozzle made it difficult to guide the PLA into exiting the machine.

Third iteration is where we worked on rectifying the previous two issues. This time a copper of small diameter was used, although that required using one heater band only. A makeshift nozzle made out of aluminum from soda cans was used in place of the drilled screw, and aluminum tapes were used to hold it in place.

Insight gained from third iteration:

Decreasing the size of the pipe made fitting the heater bands difficult, which required using aluminum foil or other conductors in between, though this seemed to have an effect on the heating quality, as the machine took a while to heat up enough to operate.

A hopper is necessary to ensure smooth operation and material infeed.

Support is very important, as later the pipe started moving in place of the drill. The assumption here is that the melted PLA was creating a strong force that was making it easier for the pipe to move rather than the drill.

Despite all this, the third iteration showed more success than the previous two iterations. Some filament was produced, but it needed to be guided out, and the machine needed to be constantly operated.